Description

Potting fibers / hollow fiber membranes (PP, PE, CA, PS, PES, PVDF...) to housings (PVC, PC, PS, glass, stainless steel) can be organized at our facility. We have extensive experience with potting hollow fiber membrane. Membrane fibers from our production is clean polypropylene and as such hydrophobic (low surface energy), difficult to bond/glue.

Potting hollow fibers for heat exchanger applications is a specific task as there are extensive peal forces on different material (different thermal expansion coefficients) joints while temperature change. Aslo temperature and pressure cycles are very demanding on potting material within its lifespan. Chemical resistance in higher temperatures should be carefully considered.

Material Selection :

Membrane material can be polypropylene (PP), polyethylene (PE), cellulose acetate (CA), polysulfone (PS), polyethersulfone (PES), polyvinylidene fluoride (PVDF) and other usually custom client formulated material. We are able to process these fibers.

Fibre material (heat exchangers), vider selection of materials can be potted. Usually PP, ABS, PC, PA, PEEK ... We are able to surface treat the fibers before potting for good adhesion without damaging the fiber or considerably lowering its life span. PEEK fibers and PA fibers are used in demanding heat exchanger applications.

Housing material, usually PVCu, PVCc, PC, PS, PEEK, glass, stainless steel… In some cases contact surface has to be primered/surface treated.

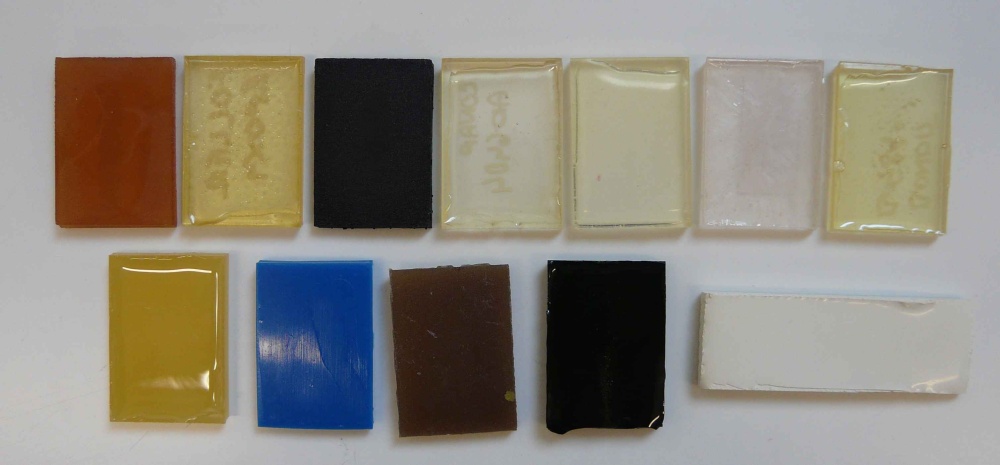

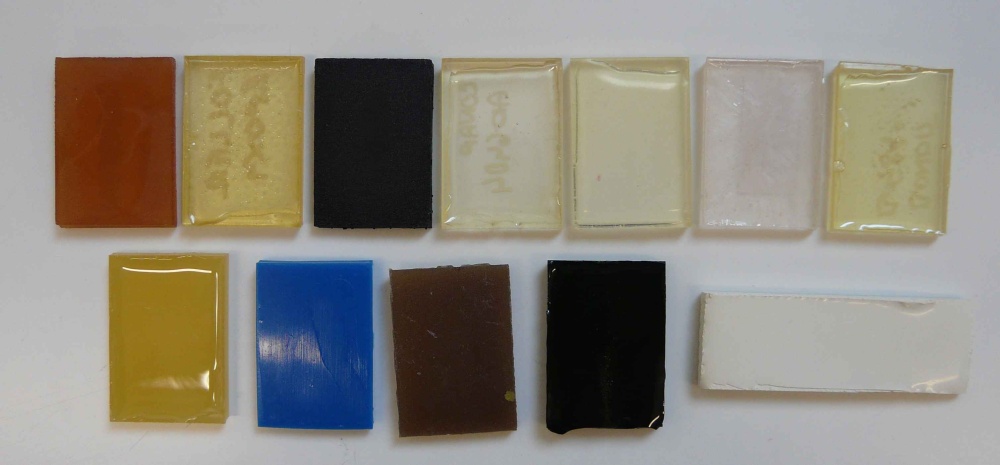

Potting materials - depending on the application potting material might have FDA, food or drinking water certification. Polyurethane potting is easier to work with as it is fast hardening and relatively soft. Epoxy potting is usually slow and hard (shore 60-85D), but is chemically and temperature more resistant. Potting with epoxy is complicated and in some cases (combination of fibre OD, materials and housing size) not possible.

Please bare in mind that there is a large variety of materials and usually when labeled PP or PS very seldom clean raw material is used. Additives will change adhesion and behaviour under stress in general. Initial adhesion testing is always good idea. Aging and fatigue are difficult to simulate, but some testing/estimates should be done before full production.

If possible due to module design, all our potted membrane fibers or fibers are integrity tested. Standard bubble point or pressure drop test is used.

Potting hollow fibers for heat exchanger applications is a specific task as there are extensive peal forces on different material (different thermal expansion coefficients) joints while temperature change. Aslo temperature and pressure cycles are very demanding on potting material within its lifespan. Chemical resistance in higher temperatures should be carefully considered.

Material Selection :

Membrane material can be polypropylene (PP), polyethylene (PE), cellulose acetate (CA), polysulfone (PS), polyethersulfone (PES), polyvinylidene fluoride (PVDF) and other usually custom client formulated material. We are able to process these fibers.

Fibre material (heat exchangers), vider selection of materials can be potted. Usually PP, ABS, PC, PA, PEEK ... We are able to surface treat the fibers before potting for good adhesion without damaging the fiber or considerably lowering its life span. PEEK fibers and PA fibers are used in demanding heat exchanger applications.

Housing material, usually PVCu, PVCc, PC, PS, PEEK, glass, stainless steel… In some cases contact surface has to be primered/surface treated.

Potting materials - depending on the application potting material might have FDA, food or drinking water certification. Polyurethane potting is easier to work with as it is fast hardening and relatively soft. Epoxy potting is usually slow and hard (shore 60-85D), but is chemically and temperature more resistant. Potting with epoxy is complicated and in some cases (combination of fibre OD, materials and housing size) not possible.

Polyurethane and epoxy potting materials, cast samples.

Please bare in mind that there is a large variety of materials and usually when labeled PP or PS very seldom clean raw material is used. Additives will change adhesion and behaviour under stress in general. Initial adhesion testing is always good idea. Aging and fatigue are difficult to simulate, but some testing/estimates should be done before full production.

If possible due to module design, all our potted membrane fibers or fibers are integrity tested. Standard bubble point or pressure drop test is used.