Gas filtration is the most common method for aerosol mitigation. It is used in many various applications such respirators and breathing systems, compressed air production, vehicle cabin air filtration, engine air intakes and exhausts, process air cleaning and demisting gas streams to remove water or oil droplets.

Last but not least it is removing nanoparticles and respirable particles such as dust, microorganisms and allergens from the indoor air to alleviate associated health concerns. The latter became of great importance as indoor air contains two to five times higher concentrations of pollutants than outdoor air.

In relation to nanotechnology and nanoparticle production, the use of membranes for air filtration has significantly increased over the past decade. Their unique performance and chemical, surface and physical properties are preferable in many air filtration applications. Other applications have been studied in greater detail, particularly air treatment using hollow fibre membranes for air humidification / dehumidification systems for air conditioning and the treatment of gases using membrane contactors.

Most recently, hollow fibre membranes for gas treatment as a subsystem of other operations such as desalination and heat pumps and non-porous hollow fibre membranes as heat exchangers have been of great interest. Pressure-flow relationships for gas flow through hollow fibre membranes Hollow fibre membranes can be used for air filtration and to provide high efficiencies in particulate matter removal down to sub-micrometric sizes when compared with classical HEPA filters.

Hollow fiber polypropylene membrane has homogenous wall structure which ensures quite large mechanical durability, but on the other hand increases trans membrane pressure drop. Membrane structure and material are suitable for cleaning chemical and back pulse. Hollow fiber membrane modules can thus be easily cleaned and restored to initial fluxes.

Hollow fiber membrane can by nicely packed (large active membrane surface / module volume ratio), but is limited on maximal particle size. If there is such possibility inflow should be pre-filtered.

As membrane is polymer there is a limit on gas/inflow temperatures.

Gas filtration hollow fiber modules are suitable for:

Gas filtration measurements

Experiments were performed with nano-aerosol particles. Three types of HFMs (Hollow Fiber Membranes) varying in packing density, active filtration area and pore-size distribution were tested in an outside-in mode. The HFM parameters are:

Last but not least it is removing nanoparticles and respirable particles such as dust, microorganisms and allergens from the indoor air to alleviate associated health concerns. The latter became of great importance as indoor air contains two to five times higher concentrations of pollutants than outdoor air.

In relation to nanotechnology and nanoparticle production, the use of membranes for air filtration has significantly increased over the past decade. Their unique performance and chemical, surface and physical properties are preferable in many air filtration applications. Other applications have been studied in greater detail, particularly air treatment using hollow fibre membranes for air humidification / dehumidification systems for air conditioning and the treatment of gases using membrane contactors.

Most recently, hollow fibre membranes for gas treatment as a subsystem of other operations such as desalination and heat pumps and non-porous hollow fibre membranes as heat exchangers have been of great interest. Pressure-flow relationships for gas flow through hollow fibre membranes Hollow fibre membranes can be used for air filtration and to provide high efficiencies in particulate matter removal down to sub-micrometric sizes when compared with classical HEPA filters.

Hollow fiber polypropylene membrane has homogenous wall structure which ensures quite large mechanical durability, but on the other hand increases trans membrane pressure drop. Membrane structure and material are suitable for cleaning chemical and back pulse. Hollow fiber membrane modules can thus be easily cleaned and restored to initial fluxes.

Hollow fiber membrane can by nicely packed (large active membrane surface / module volume ratio), but is limited on maximal particle size. If there is such possibility inflow should be pre-filtered.

As membrane is polymer there is a limit on gas/inflow temperatures.

Gas filtration hollow fiber modules are suitable for:

- Very clean low volume gas filtration applications

- Gas sampling units

Gas filtration measurements

Experiments were performed with nano-aerosol particles. Three types of HFMs (Hollow Fiber Membranes) varying in packing density, active filtration area and pore-size distribution were tested in an outside-in mode. The HFM parameters are:

| HFMs | P50 | P60 | P80 |

| Fibre outer diameter, Do (μm) | 300 | 300 | 620 |

| Fibre inner diameter, Di (μm) | 228 | 228 | 474 |

| Fibre wall thickness, tw (μm) | 36 | 36 | 73 |

| Number of fibres, n | 1380 | 1380 | 300 |

| HFMs net length (mm) | 730 | 730 | 730 |

| Potting thickness (mm) | 5 | 15 | 15 |

| Membrane packing density, αM (%) | 46 | 46 | 43 |

| Bundle inner diameter, Dbi (mm) | 16.4 | 16.4 | 16.4 |

| HFM surface area (m2) | 0.95 | 0.95 | 0.43 |

| Initial TMP (5 cm/s) (Pa) | 543.2 ± 3.3 | 558.6 ± 3.6 | 284.6 ± 2.7 |

| Average pore size (nm) | 94 | 87 | 95 |

| Porosity, ε (%) | 52 | 52 | 54 |

| Average collector diameter, df (nm) | 130 | 90 | 112 |

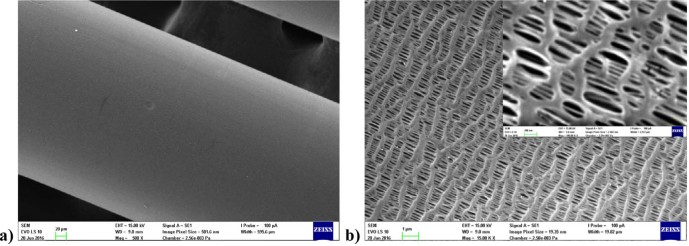

SEM of HFM shell side: a view of a single fibre (a) and a detail of porous surface (b).

Particle counting was carried out using a TSI 3075 condensation particle counter connected to a TSI 3080 scanning mobility particle sizer in 48 particle size channels from 18.1 to 100 nm.

Due to their high efficiency, HFMs may be used for special applications in which low volume flowrates are involved. A brief summary follows:

- The results show high efficiency for removal of submicron particles. The MPPS were in the range of 34–40 nm with high efficiency at a velocity of 5 cm/s and decreased in the following order: P60 > P80 > P50 (for MPPS). With increasing permeate velocity, the MPPS efficiency decreased down to 69% (15 cm/s). Nonetheless, for particle sizes above 60 nm, the efficiency remained practically unchanged no matter the permeate velocity.

- TMP (Transmembrane Pressure) is rather higher compared to fibrous air filters. P50 and P60 are almost the same as they have the same parameters and were around 560 Pa at 5 cm/s. P80, with double the fibre diameter though half the filtration area, had TMP of 285 Pa at the same permeate velocity, which is comparable to fibrous HEPA filters. TMP remains the main problem to practical applicability as this parameter determines the energy consumption of the overall filtration process.

- Polypropylene HFMs were further compared in terms of QF (Quality Factor), which is often appropriate. QF was comparable with fibrous filters and the other HFMs reported previously mainly for MPPS of P80 while rather higher for larger particle sizes (those above 60 nm). P60 had a higher efficiency compared to P80 though a lower QF due mainly to higher TMP.

For details see:

Pavel Bulejko, Mirko Dohnal, Jiří Pospíšil, Tomáš Svěrák, Air filtration performance of symmetric polypropylene hollow-fibre membranes for nanoparticle removal, Separation and Purification Technology 197 (2018) 122–128