Membrane Contactors are used for degassing liquids extensively, especially for O2 and CO2 removal from water. Systems with membrane contactors are quite effective and compact in size due to this they have largely replaced vacuum towers, forced draft deaerators, and oxygen scavengers.

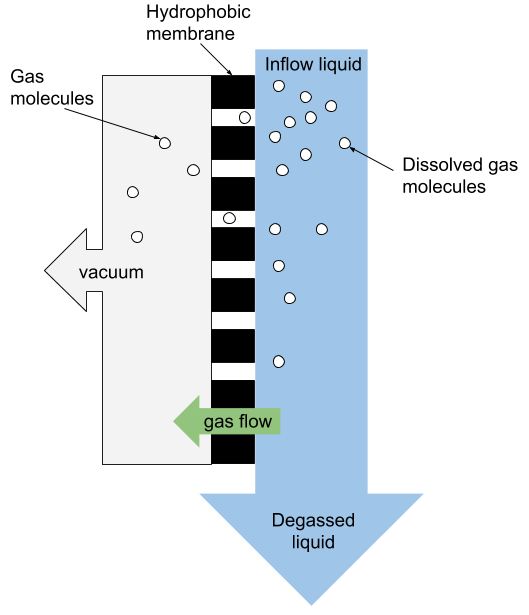

When inside / out hollow fiber membrane module is used, water degassing can be quite effective. Due to small fiber diameter there will be some pressure drop, this can be partly compensated by large module cross section(large fibre count). Inflow/water, relatively clean of mechanical particles is fed to lumen of the membrane fiber. In the shell is created vacuum. Gas from liquid will be removed.

For certain application (embedded or large power plants) immersed modules can be used, depending on the setup.

Degassing / deaeration of liquids is needed in:

Our polyolefin membrane (PP) has low surface tension and as such is suitable even for fluids such as ink jet printing inks, emulsions, paint coating solutions and other surfactant solutions. For extreme cases membrane surface can be surface treated to lover surface tension.

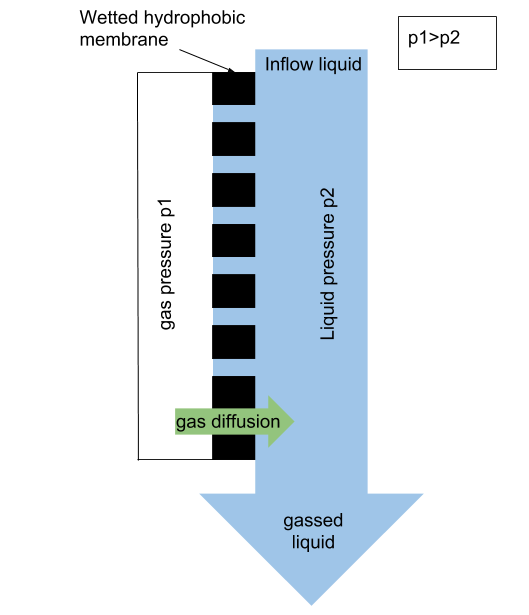

For certain application(algae production) it is important gas liquid without bubbles. This can be easily done through membrane assisted diffusion.

Module production is modular and be easily customized to required application.

When inside / out hollow fiber membrane module is used, water degassing can be quite effective. Due to small fiber diameter there will be some pressure drop, this can be partly compensated by large module cross section(large fibre count). Inflow/water, relatively clean of mechanical particles is fed to lumen of the membrane fiber. In the shell is created vacuum. Gas from liquid will be removed.

For certain application (embedded or large power plants) immersed modules can be used, depending on the setup.

Degassing / deaeration of liquids is needed in:

- Power plants

- Microelectronics production

- Food & beverage production

- Pharmaceutical production and labs

- Industrial chemicals production

- Ink and paint production

Our polyolefin membrane (PP) has low surface tension and as such is suitable even for fluids such as ink jet printing inks, emulsions, paint coating solutions and other surfactant solutions. For extreme cases membrane surface can be surface treated to lover surface tension.

For certain application(algae production) it is important gas liquid without bubbles. This can be easily done through membrane assisted diffusion.

Module production is modular and be easily customized to required application.

Contactor degassing / deareation

Contactor degassing / deareation

Membrane gassing (no bubbles)