Description

Lab Rord Module is compatible with most of the desk-top bioreactors (fermenters) such as BioFlo from Eppendorf. Shape of a rod (usually d20 or d12mm) allows o-ring seal and easy positioning in bioreactor. Dead end hollow fiber membrane setup is used. Port connection usually hose barb trough thread.

Used in:

Suitable for filtration and contactor applications while bioprocess is active, no need for batch process. In filtration setup, permeate can drawn out of bioreactor without interrupting cultivating process and thus eliminating setup times. Lab rod module can be use for certain applications (algae for example), where there is a need for bubble-less controlled gassing / degassing the cultivating process.

Used in:

- Biotech labs

- Pharmaceutical labs

Suitable for filtration and contactor applications while bioprocess is active, no need for batch process. In filtration setup, permeate can drawn out of bioreactor without interrupting cultivating process and thus eliminating setup times. Lab rod module can be use for certain applications (algae for example), where there is a need for bubble-less controlled gassing / degassing the cultivating process.

Specifications

Module characteristic

|

Membrane |

P60 |

|

Active membrane length |

220 mm |

|

Mmebrane fibers |

500 |

|

Membrane surface |

1 000 cm2 |

|

pH resistance |

2-11 |

|

Max working temperature |

40°C |

|

Rod diameter |

12 mm |

|

Port |

hose barb * |

|

Materials |

PP, PU, PVCu |

* Connections can be easily customized

Datasheet download

Technical drawing download

Application

Bioreactor (biofermenter / fermenter) definition

Bioreactor is a container in which a chemical process is carried out which involves biochemically active substances derived from microorganisms. Organisms growing in bioreactor are submerged in liquid medium. Cultures may be suspended or immobilized.

Usage of Hollow Fiber Lab Fermenter:

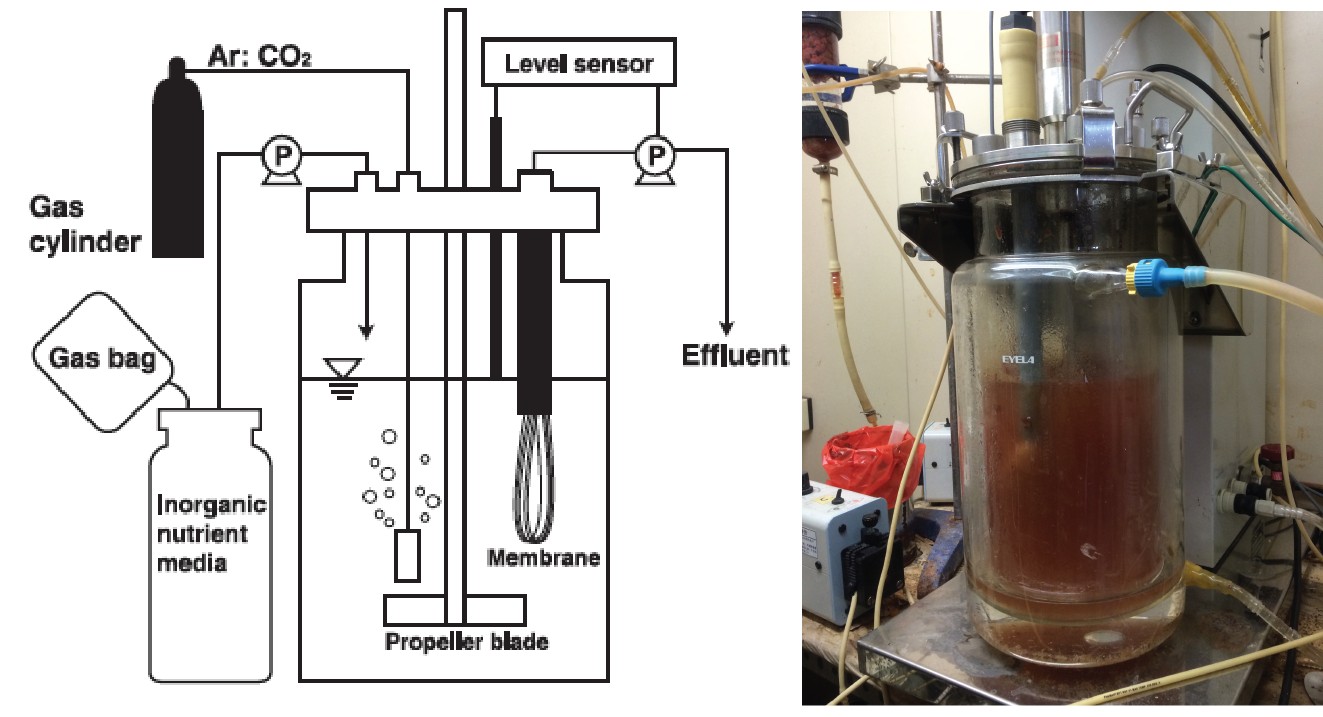

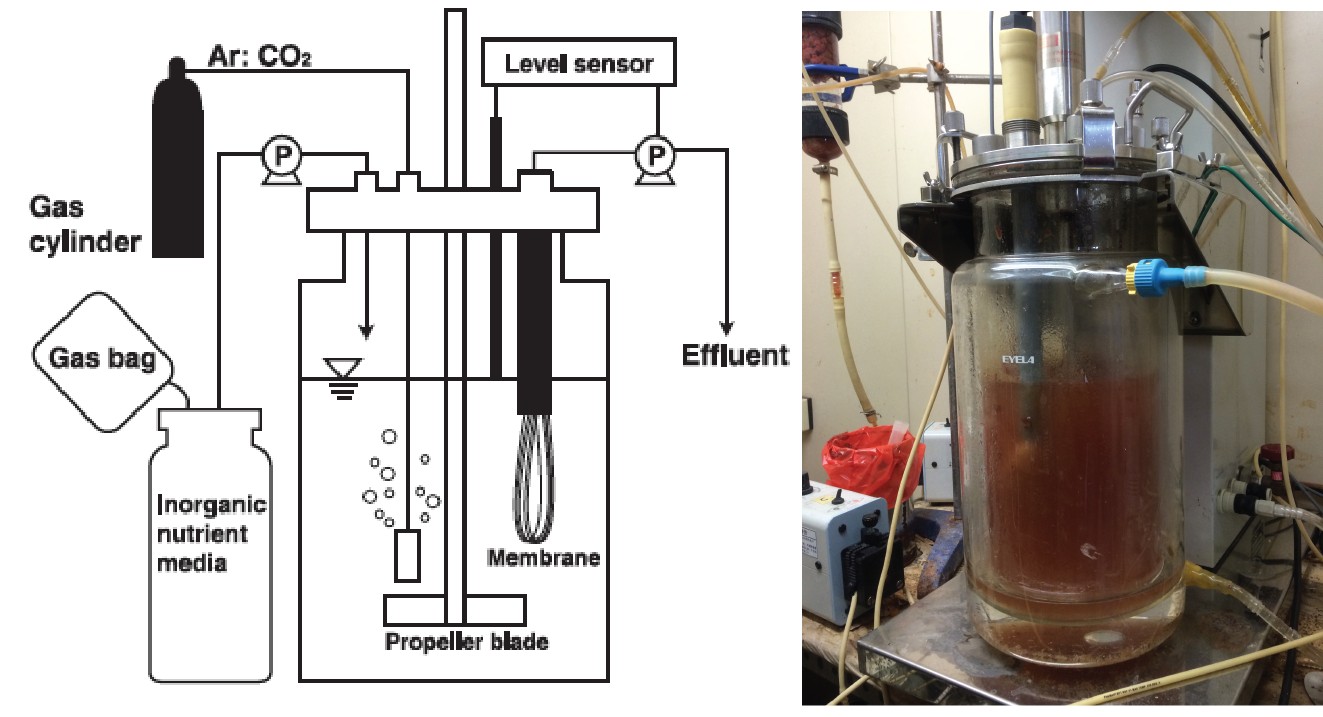

Sample custom application - BioConSepT (2012-2015)

The aim of the cooperation project was biotechnological production of fuels and chemicals from renewable biomass. BioConSepT has developed 8 different processes to produce multifunctional molecules (e.g. biosurfactants, acids) from lignocellulosic and oil feedstock.

The role of ZENA in project was solved In Situ Product Recovery for improving the fermentation performance. Separation of the cells from the liquid phase is necessary for the further purification of product. An integrated fermentor with ultrafiltration membranes was developed.

BioConSepT (2012-2015)

Bioreactor is a container in which a chemical process is carried out which involves biochemically active substances derived from microorganisms. Organisms growing in bioreactor are submerged in liquid medium. Cultures may be suspended or immobilized.

Usage of Hollow Fiber Lab Fermenter:

- Isolation (extract) of active substances (product) - extractive membrane bioreactor

- Nutrition, aeration of substrate during a biconversion - membrane aeration bioreactor

- Immobilisation microorganisms inside a hollow fibers

Sample custom application - BioConSepT (2012-2015)

The aim of the cooperation project was biotechnological production of fuels and chemicals from renewable biomass. BioConSepT has developed 8 different processes to produce multifunctional molecules (e.g. biosurfactants, acids) from lignocellulosic and oil feedstock.

The role of ZENA in project was solved In Situ Product Recovery for improving the fermentation performance. Separation of the cells from the liquid phase is necessary for the further purification of product. An integrated fermentor with ultrafiltration membranes was developed.

BioConSepT (2012-2015)