Description

For industry lab or medical product membrane module has to be customized to fit required space or other needs of the application. OEM solutions are possible even as a product replacement.

Our engineering is able to design membrane housing (machining, mold casting or mold injection) and whole membrane module production according to the specifications.

We use several in-house modular module systems:

PVCu based system

This is most common system as it is cheap, there is large variety of fittings reductions and connections. Parts are glued with solvent glue(drinking water certification), joint is strong and reliable. Standard production line from GF or VDL is in dimensions 20, 25, 32, 40, 50, 63, 75, 90mm. Housing basic shell can be constructed out of pipes of these dimensions. T-pieces and reductions are usually used as ports. Module with variable length (10-100cm), 2 lumen ports and one or more shell ports can be easily produced. In this system there is a slight dimension and material markup, joints pipes and fittings are designed to 10bar or more pressure rating.

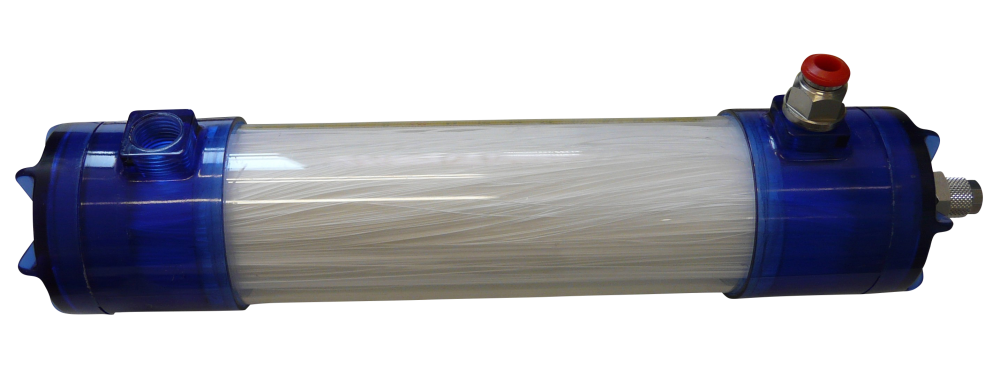

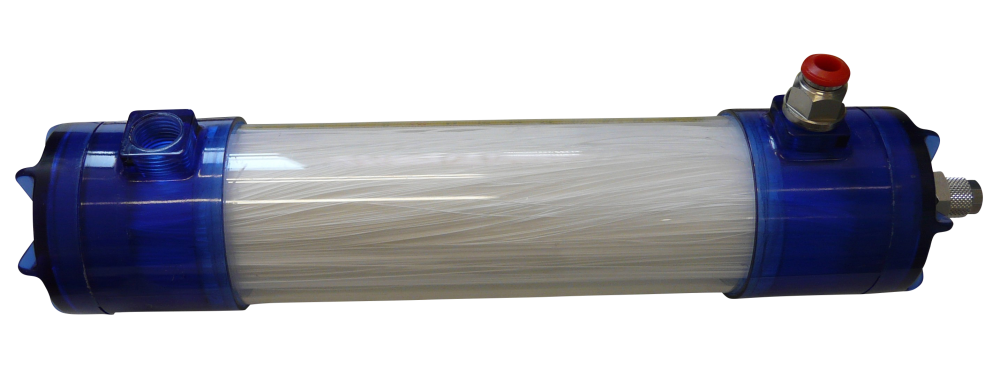

Polycarbonate based system

We are currently able to work only with d50mm. System consists of PC pipe, PC cap ¼ female port and PC shell port female thread ¼. Parts are welded together, joint is strong and reliable. Module with variable length (10-100cm), 2 lumen ports and one or more shell ports can be easily produced.

Full custom or supplied housing and or membrane

Full customization is also possible, but is expensive especially in small batch production. Machining is done contractually in tested local workshops.

Custom module design our or other membrane various OEM solutions

Our engineering is able to design membrane housing (machining, mold casting or mold injection) and whole membrane module production according to the specifications.

We use several in-house modular module systems:

PVCu based system

This is most common system as it is cheap, there is large variety of fittings reductions and connections. Parts are glued with solvent glue(drinking water certification), joint is strong and reliable. Standard production line from GF or VDL is in dimensions 20, 25, 32, 40, 50, 63, 75, 90mm. Housing basic shell can be constructed out of pipes of these dimensions. T-pieces and reductions are usually used as ports. Module with variable length (10-100cm), 2 lumen ports and one or more shell ports can be easily produced. In this system there is a slight dimension and material markup, joints pipes and fittings are designed to 10bar or more pressure rating.

Polycarbonate based system

We are currently able to work only with d50mm. System consists of PC pipe, PC cap ¼ female port and PC shell port female thread ¼. Parts are welded together, joint is strong and reliable. Module with variable length (10-100cm), 2 lumen ports and one or more shell ports can be easily produced.

Full custom or supplied housing and or membrane

Full customization is also possible, but is expensive especially in small batch production. Machining is done contractually in tested local workshops.

Custom module design our or other membrane various OEM solutions